How to Keep Your Equipment Up and Running?

Your business' Facilities and Fixed Assets are the most valuable elements of your business so keeping them in tip-top condition is crucial. Not only for your business operations but also to keep costs down. Without preventive maintenance schedules in place and quality preventing maintenance software technology systems, you run risk of equipment slowdown, unplanned downtime due to breakdowns and you pose a safety risk to your staff. In this piece, we'll discuss how to keep your business equipment up and running to stay efficient, prolong its lifecycle and reduce maintenance cost by putting into place a suitable maintenance management system. Don't fall victim to just thinking your equipment will look after itself – it won't, and it could be potentially dangerous too. Read on for our tips on how to keep equipment ship-shape with predictive maintenance.

1. Keep All the Information in One Place

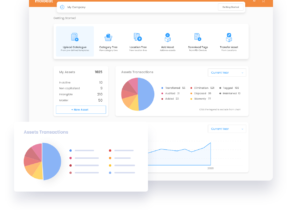

That means the user manual, the warranty information, value of equipment, date of purchase and anything else pertinent. A Fixed Asset Management System is an invaluable piece of technology that records all of this information, tracks depreciation and a CMMS software maintenance system such as Mojodat Maintenance to complement this type of technology will automatically schedule maintenance in advance, flagging up when maintenance is due so your team can build in downtime. A CMMS Preventative Maintenance Software system will also create work orders, freeing up your maintenance operations' team to concentrate on other aspects of their job.

2. Read the Instruction Manual

It's obviously important to store the manual for each Equipment and Fixed Asset carefully but it's equally essential to read and digest the information to understand simple error codes and troubleshooting. Sometimes, simple errors can be dealt with in-house, reducing the need to call in a technician, saving time and money.

3. Never Scrimp On Equipment

Sometimes it's tempting to buy a piece of machinery that perhaps isn't quite up to the job at hand just to cut costs, but it's better to spend a little more to get a better-quality product. You need all of your machinery to run efficiently as slowdowns or machinery that doesn't have all the features you need can end up costing you more, as you'll need to replace it quicker than you anticipated. So, before purchasing any equipment, think about everything you want it to do for you but also think of the future – especially if you plan to grow, will the piece of machinery you're planning to purchase still be up for the job as you expand?

4. Ensure Relevant Staff are Well-Trained

With every new piece of kit delivered to your business, get to grips with it thoroughly before putting it into use. Test runs are essential as is staff training. All relevant employees must understand how to use machinery so set up sufficient staff training to ensure it is used correctly.

5. Perform Regular Fixed Asset Audits

All machinery must be regularly inspected with thorough audits carried out every few months. If machinery is used repeatedly, it will experience wear and tear so it must be checked to ensure that small issues don't become big problems. Every Fixed Asset should be monitored through a CMMS System that holds all of its maintenance needs in one place. A good CMMS System will flag up when maintenance is due and also deliver alerts when problems occur to prevent them slowing down your business. Used properly, your CMMS System should assign work orders. Plus, regular reports and insights give you an overview of your assets' performance and whether or not you need to purchase spare parts or replace an item. CMMS is designed to streamline your operations, reduce maintenance downtime, and prolong the life of your machinery and equipment.

6. Assign Tags to Your Fixed Assets

You should also assign tags to all of your Fixed Assets that tracks their whereabouts and usage. Using a mobile handheld application (with maintenance mobile apps for example), you can easily see who's used your Fixed Assets, when they were used and see where they are through QR coding, barcoding, or RFID tagging. This helps with inventory management, depreciation and tracking maintenance too, another excellent software system that you would benefit from is Mojodat Inventory.

7. Never Put Off Replacing Machinery or Equipment Parts

If your Fixed Assets are showing signs of wear and tear and your CMMS System is flagging up alerts that parts need changing, never put this off! This is as much for user safety as it is for efficiency in your business. If you fail to replace spare parts, when necessary, you will undoubtedly experience a machinery breakdown and that can completely bring a production line (for example) to a grinding halt! Worse still, you put the safety of your employees in danger.

8. Keep Your Equipment Clean

Machinery maintenance also means cleaning. If your equipment gets especially dirty (perhaps food manufacturing or construction for example), it must be kept meticulously clean as grime builds up which can result in breakage or slowdowns. Follow the instructions in the manual and at the end of a shift, clean up your equipment so it's ready for the next shift.

9. Store Equipment Properly

As well as cleaning, storage is important. If your equipment isn't weatherproof for example and you keep it outdoors, don't expect it to last its maximum life. Indoor equipment and outdoor equipment should always be stored according to the manual and if it's not required for a while, it should be carefully kept in storage until needed and then a thorough test run performed before it is put to work again.

10. Evaluate Old Equipment

Your Fixed Asset Management System tells you about depreciation and when you can be expected to replace old equipment. As your machinery gets older, it may become more problematic but sometimes, if you look after equipment, you can prolong its life. If you have machinery that still works efficiently, schedule in extra preventive maintenance to make sure that it still operates safely and continues to deliver what you expect.

Subscribe to read the full article below.